BAOJI ENERGY TITANIUM CO.,LTD.

Add:No.68 baoti road,hi-tech

zone,baoji,shaanxi,China.721013.

Email:emily@energytitanium.com

Tel: +86-917-3437683

Fax:+86-917-3437683

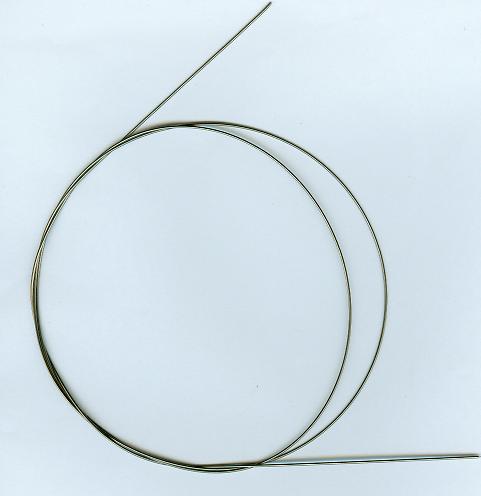

Nitinol wire (TiNi Shape Memory Alloy Wires)

1.Name: Nitinol wire (TiNi Shape Memory Alloy Wires)

2.Material: mainly Nickel and Titanium

3.Standard:ASTM F2063-05,Q/XB1516 Customer specified or Industry Standard

4.Size:Wire--0.05-6.0mm

Bar--above Dia6.0mm

Sheet--Thickness 0.3-50.0mm Width≤350mm Length≤2500mm

5.Chemical composition:Ni: 55.4% --56.2% C≤0.07 H≤0.005 O≤0.050 N:≤ 0.05

6.Aplication : Widely used in the dental arch wire, interventional stent wire, surgical sutures,

medical guide wire,eyeglass frames, mobile phone antennas and bra stand.

Quick details

|

Grade |

Transformation Temperature AF |

Form |

Standard |

|

|

Shape Memory Nitinol Alloy |

Ti-Ni-01 |

20 °C~ 40 °C |

Wire,bar,plate |

Customer specified or Industry standard |

|

Ti-Ni-02 |

45 °C~ 90 °C |

Wire,bar,plate |

||

|

Superelastic Nitinol Alloy |

TiNi-SS |

-5 °C~ 5 °C |

Wire,bar,plate |

|

|

Low Temperature Superelastic Nitinol Alloy |

TN3 |

-20°C~-30°C |

Wire,bar,plate |

|

|

TNC |

||||

|

Medical Nitinol Alloy |

TiNi-SS |

33 ± 3 °C |

Wire,bar,plate |

ASTM F2063 |

|

Narrow Hysteresis Nitinol Alloy |

Ti-Ni-Cu |

As-Ms ≤ 5 °C |

Wire,bar |

|

|

Wide Hysteresis Nitinol Alloy |

Ti-Ni-Fe |

As-Ms ≤ 150 °C |

Wire, bar |

Specifications

|

Alloy |

Chemical composition |

Af (Fully annealed) |

Min. elongation to failure [%] |

Max. Residual elongation after 6% strain [%] |

Main Applications |

Specifications |

|

|

Superelastic Ni-Ti alloy |

TiNi-SS |

Ti-50.8at% |

-5°C ± 5°C. |

10 |

0.1 |

Eyeglass Frames, Cellular Phone Antennae, Bra Underwire |

Q/XB1516.2 Q/XB1516.2 |

|

TN3 TNC |

TiNiVAl TiNiCr |

-40°C ~50°C |

10 |

0.1 |

|||

|

Body temperature Ni-Ti alloy |

TiNi-YY |

Ti-50.7at%Ni |

Functional Af=33 ± 3 |

15 |

0.1 |

Implantable devices,Bone staples Vascular Stents |

ASTM 2063 |

|

Ti-Ni-01 |

55.6~55.8 wt%Ni |

20 - 40 |

15 |

0.1 |

Guide wires, Stents Orthodontic Arches |

Q/XB1516.1 |

|

|

High temperature Ni-Ti alloy |

Ti-Ni-02 |

54.8~55.5wt%Ni |

45 - 95 |

10 |

0.1 |

Implantable active devices, Surgical tools, Thermostats Coffeepots |

Q/XB1516 |

|

TiNiCu |

TiNiCu |

As-Ms ≤ 5 |

10 |

0.1 |

|||

|

Density (g/cm^3) |

6.45 |

|

Melting point (°C ) |

1240-1310 |

|

Specific heat capacity( kJ/(kg·°C) |

0.46 |

|

Coefficient of thermal conductivity (W·m-1·K-1) |

10 |

|

Resistivity (10-6 Ω·m) |

80 |

|

Expansion coefficient (10-6 Ω·K-1 ) |

10.4 |

|

Elastic modulus (GPa) |

40-80 |

|

HV |

180-200 (low-temperature metallography) 200-350 (high-temperature metallography) |

|

Tensile strength (MPa) |

700-1100 |

|

Yield strength |

50-200 (low-temperature metallography) 100-600 (high-temperature metallography) |

|

Elongation δ % |

20-60 |

|

phase transition temperature (Af / °C) |

-10-100 |

|

Recovery response variable % |

8, 6, 2 , <0.5 |

|

Utmost service temperature (°C ) |

Af +60, 250 |

|

Maximum recovery stress (Mpa) |

680 |

| Previous:Titanium smoking nail Next:Medical titanium sheet and plate |